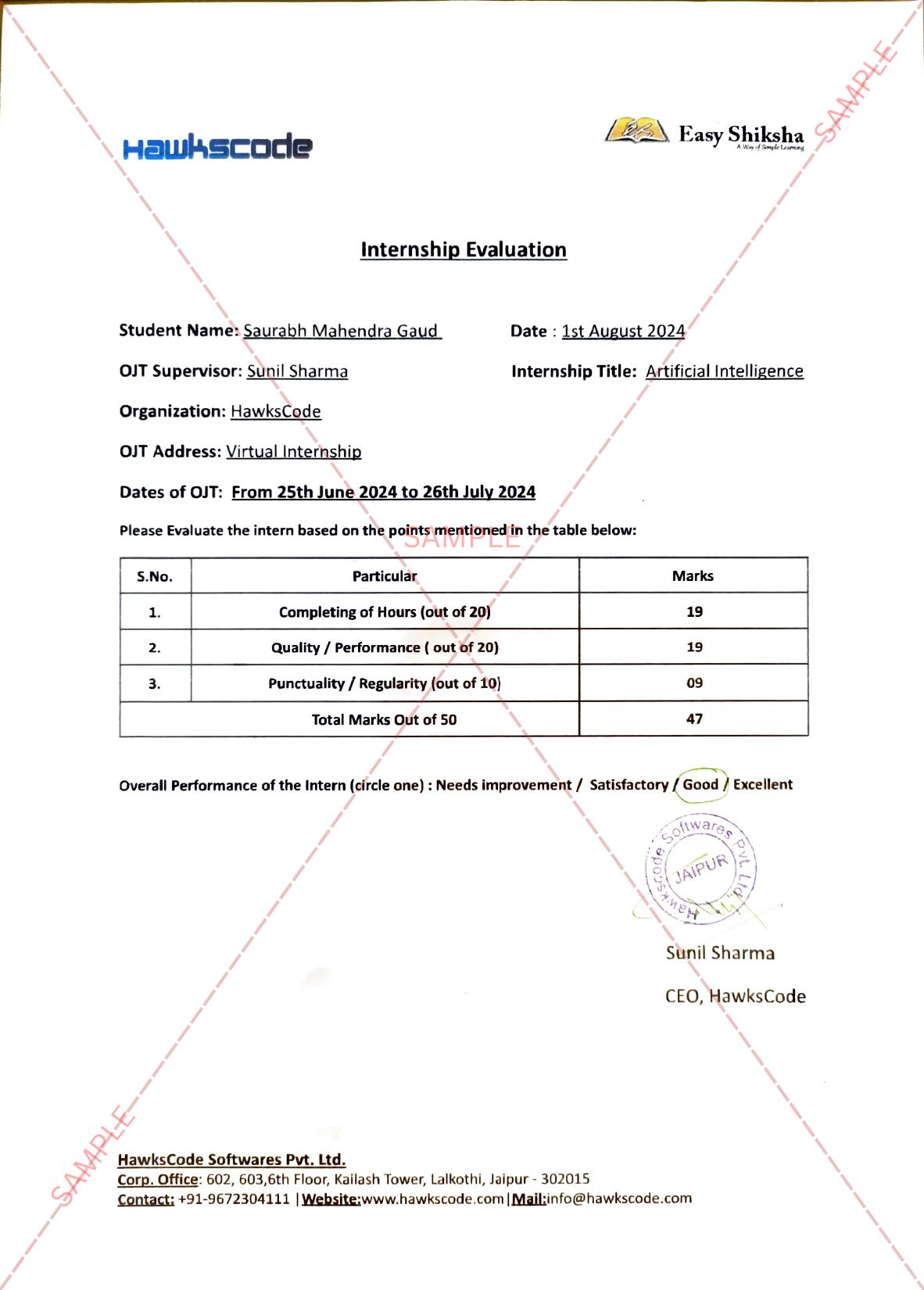

Reverse Engineering Process

In my previous blog I had given you an intro to Reverse Engineering but, In this blog, we are going to discuss the Reverse Engineering Process and the reasons for reverse engineering. To get the best out of this blog you need to read my previous blog.

Reverse engineering is very common in such diverse fields as software engineering, entertainment, automotive, consumer products, microchips, chemicals, electronics, and mechanical designs. In many situations, designers use CAD models, clay, plastic, wood, etc. But, a CAD model is required to give shape to there design.

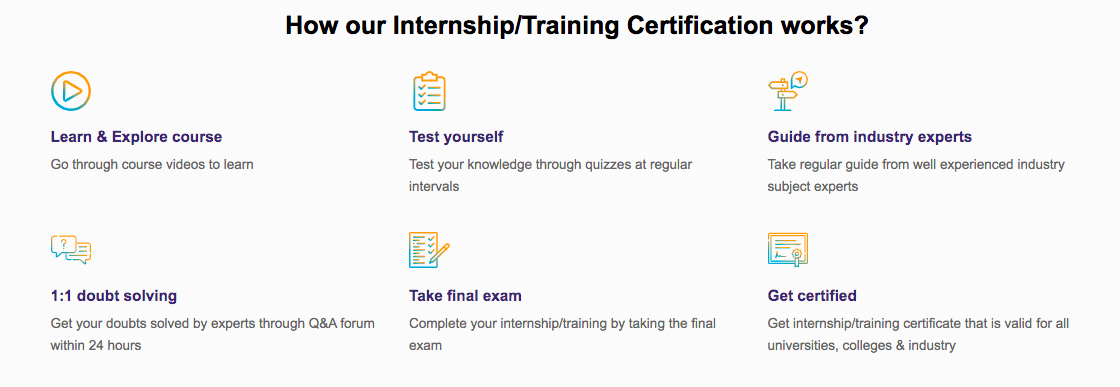

The original manufacturer stop produces the product, inadequate documentation, some bad feature of product need to redesign it again, to analyze good and bad features of competitor products and methods to understand competitor products and develop a better product. To Learn about reverse engineering and deep learning concept visit Easyshiksha Online Courses.

Important Announcement – EasyShiksha has now started Online Internship Program “Ab India Sikhega Ghar Se”

The Steps of Reverse Engineering process includes

1.Collection Information:

This step focuses on collecting all possible information about the software, the purpose, how does it work, design documentation, etc.

2.Examining the information:

Now we need to observe and examine the working of product, meeting design objectives.

3.Extracting the structure:

This step concerns with identification of program structure in the form of a structure chart where each node corresponds to some routine. We need to disassemble and examine the different parts.

4.Recording the functionality, data flow, and control flow:

During this step processing details of each module of the structure, charts are recorded using structured language like decision table, etc.

From the information get after extracted the structure and functionality, a set of data flow diagrams are derived to show the flow of data among the processes and after this High-level control structure of the software is recorded.

5. Review and analyze the extracted design:

Design document extracted is reviewed several times to ensure consistency and correctness. It also ensures that the design represents the program.

6.Generate documentation:

After analyzing and carefully resemble the product the complete documentation including SRS, design document, history, overview, etc. are recorded for upgrades and changes.

Top Courses in Software Engineering

More Courses With Certification

I hope to know you understand the steps involve in Reverse Engineering Process and to learn more tech blogs like this visit HawksCode and Easyshiksha.

Empower your team. Lead the industry

Get a subscription to a library of online courses and digital learning tools for your organization with EasyShiksha

Request NowALSO READ: in-times-of-corona-wealth-clinic-comes-up-with-earning-opportunity

Get Course: Google-Adwords-for-Beginners